Structural metals experience changes in their properties when they are cooled from room temperature to “subzero†temperature range. However, in arctic regions, where temperatures drop to as low as -70°C (-95°F), carbon steels become embrittled. To determine how a metal will exhibit mechanical properties at sub zero temperatures, Cryogenic Impact testing is performed on test piece.

A notch is made on the test piece and the same is chilled to sub zero temperatures using liquid Nitrogen (-321° F /-160° C) or liquid Helium (-452° F/-233° C) inside a cold box for a period of minimum 2 hours. It is then subjected to Impact test where the properties are ascertained based on the failure surface or deformation of the test piece.

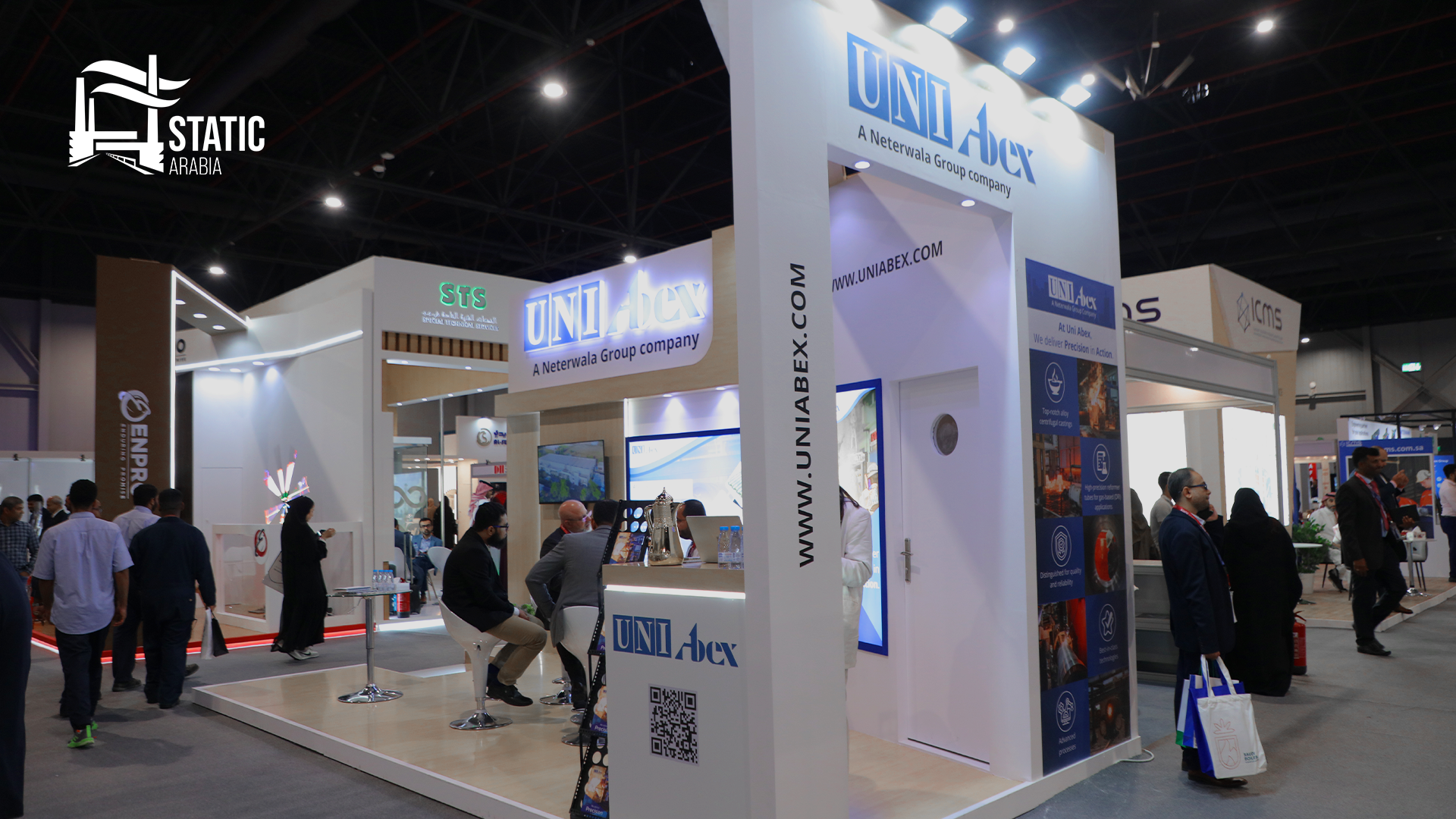

UNI Abex offers in-house Cryogenic Impact Testing for materials intended for application in sub zero temperatures.

.jpg)